Based out of San Diego, Decisive Testing provides Non Destructive Testing (NDT/NDE) and X-Ray inspection services for residential and commercial customers. When founded in 1968 our primary focus was on commercial x-ray inspection of welds and concrete. Over fifty years later our capabilities have grown to include nearly all forms of non-destructive testing as well as many destructive and mechanical test methods.

Concrete Scanning (GPR), X-Ray, and Utility Locating

Prior to cutting, coring, or drilling into a concrete structure it is usually necessary to identify sub surfaces features that shouldn’t be compromised. This could be rebar, post-tension cables (tendons), electrical conduit, plumbing, gas lines, or any number of things. At Decisive Testing, we can provide multiple technologies to assist in identifying these features.

Our capabilities include:

- Film and digital x-ray using either conventional x-ray or gamma sources.

- Ground Penetrating Radar (GPR)

- Utility Locating (passive and/or active scan as well as sonde)

In general, GPR and utility locating are the most common technologies used with our residential customers while a combination of GPR and X-Ray is more common for commercial (apartments, high rises, etc.) Our experienced staff can assist you in determining the appropriate technology for your project.

Industrial and Materials X-Ray

Decisive Testing provides radiographic (x-ray) inspection services at our main campus in San Diego as well as field (on-site) locations. Depending on scope of work, field locations are served by one or more darkroom trucks and/or a mobile satellite office (trailer).

Our licensed & certified technicians have access to digital as well as traditional (film) imaging methods both in shop and in the field

Our capabilities include:

- Conventional x-ray or gamma sources

- Digital flat panel detectors with 150-250µm resolution

- We have six X-Ray booths located at our San Diego facility

- Our mobile fleet currently includes five darkroom trucks and two portable darkroom trailers

Over the last fifty years Decisive has performed x-ray inspection on an extensive array of products. Our x-ray inspection experience includes:

- Multiple water, fuel, and gas pipelines

- 100% of all welds on a first of class geothermal plant

- Structural steel weldments

- Aerospace castings and composite components

- Consumer electronics

- Welder qualifications

Metallurgical, Mechanical, And Pressure

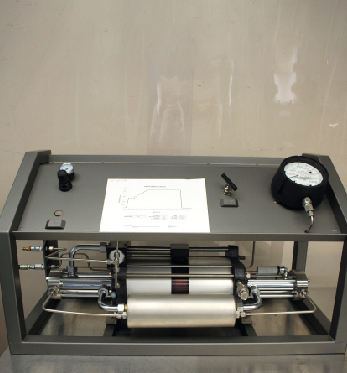

We have a full metallurgical and mechanical testing facility located at our main campus. Our equipment and capabilities include:

- Multiple universal testing (tensile/compression) machines with capacity to 130,000lbs

- Bend test

- Alloy Identification using both Glow Discharge Spectroscopy and XRF

- Hardness (all scales)

- Macro and Micro analysis (weld profile, grain size/structure, etc.)

- Charpy Impact (room and reduced temperature)

Additionally, we provide a wide range of pressure and leak test inspections including:

- Helium Leak test

- Hydrostatic proof and burst test

- Gas (nitrogen/dry air/helium) proof and burst test

- Most tests can be performed at elevated temperatures as required